DS51402A

REQUIREMENTS:

1.

Type. Cold forged (type A, style 1 of procurement specification).

2.

Material. Steel, carbon, 345 MPa minimum tensile strength; Brass, commercial.

Protective finish. Steel nuts, cadmium plated per SAE-AMS-QQ-P-416, type II, class 3

3.

(5.1 μm thick).

4.

Threads. "M" profile, coarse pitch, tolerance class 6H in accordance with FED-STD- H28/21.

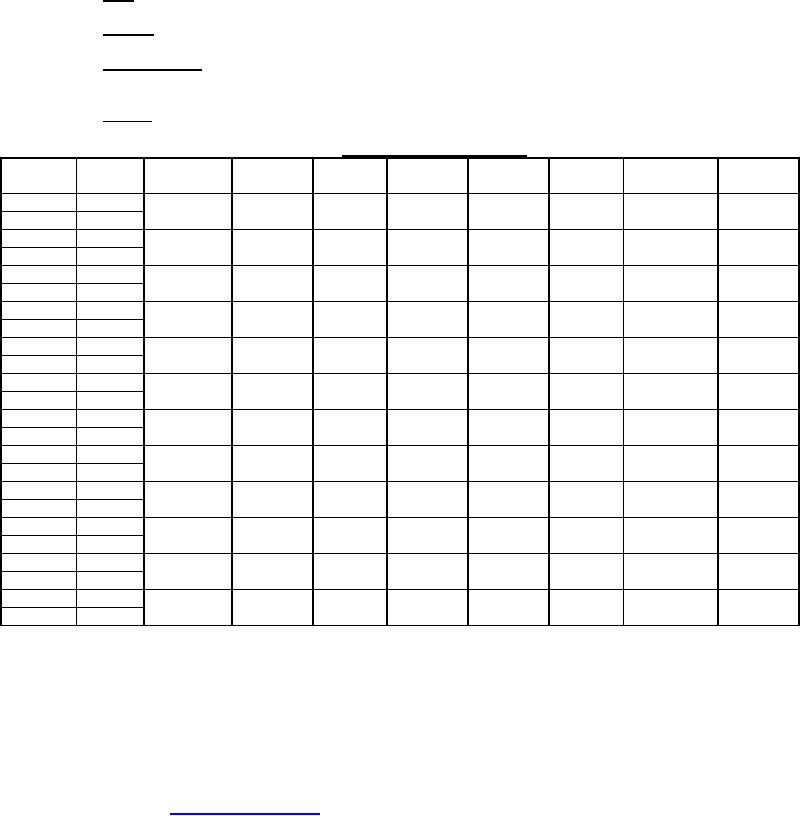

TABLE I. Dimensions and dash numbers

Dash

Material

A

B

C

D

E

F

G

H

Number

-01

Steel

M2X0.4

20 ± 0.65

10 ± 0.45

8 ± 0.45

5 ± 0.38

6 ± 0.38

1.6 ± 0.30

2 ± 0.30

-02

Brass

-03

Steel

M2.5X0.45

20 ± 0.65

10 ± 0.45

8 ± 0.45

5 ± 0.38

6 ± 0.38

1.6 ± 0.30

2 ± 0.30

-04

Brass

-05

Steel

M3X0.5

20 ± 0.65

10 ± 0.45

8 ± 0.45

5 ± 0.38

6 ± 0.38

1.6 ± 0.30

2 ± 0.30

-06

Brass

-07

Steel

M4X0.7

20 ± 0.65

10 ± 0.45

8 ± 0.45

5 ± 0.38

6 ± 0.38

1.6 ± 0.30

2 ± 0.30

-08

Brass

-09

Steel

M5X0.8

25 ± 0.65

12 ± 0.55

10 ± 0.45

6 ± 0.38

8 ± 0.45

2 ± 0.30

2.5 ± 0.30

-10

Brass

-11

Steel

M6X1

32 ± 0.80

16 ± 0.55

12 ± 0.55

8 ± 0.45

10 ± 0.45

2.5 ± 0.30

3 ± 0.30

-12

Brass

-13

Steel

M8X1.25

40 ± 0.80

20 ± 0.65

16 ± 0.55

10 ± 0.45

12 ± 0.55

3 ± 0.30

4 ± 0.38

-14

Brass

-15

Steel

M10X1.25

50 ± 0.80

25 ± 0.65

20 ± 0.65

12 ± 0.55

16 ± 0.55

4 ± 0.38

5 ± 0.38

-16

Brass

-17

Steel

M12X1.75

64 ± 0.95

32 ± 0.80

23 ± 0.65

14 ± 0.55

19 ± 0.65

5 ± 0.38

6 ± 0.38

-18

Brass

-19

Steel

M16X2

72 ± 0.95

36 ± 0.80

28 ± 0.65

16 ± 0.55

22 ± 0.65

6 ± 0.38

7 ± 0.45

-20

Brass

-21

Steel

M20X2.5

90 ± 1.1

45 ± 0.80

36 ± 0.80

20 ± 0.65

28 ± 0.65

7 ± 0.45

9 ± 0.45

-22

Brass

-23

Steel

M24X3

112 ± 1.1

56 ± 0.95

45 ± 0.80

24 ± 0.65

36 ± 0.80

9 ± 0.45

11 ± 0.55

-24

Brass

Custodians:

Preparing activity:

Army AR

DLA IS

Air Force 99

(Project 5310-2725-000)

NOTE: The activities listed above were interested in this document as of the date of this document. Since

organizations and responsibilities can change, you should verify the currency of the information above using the

ASSIST Online database at https://assist.daps.dla.mil/.

2