MIL-DTL-70329A

3.5.2 Phosphate coating. Phosphate coating shall conform to MIL-DTL-16232, type Z, class 2..

3.5.3 Cleaning and descaling. Corrosion-resistant steel shall be cleaned and descaled in accordance with

ASTM A380.

3.6 Cracks, seams, inclusions, and flaws. Nuts shall be free from cracks, seams, inclusions, and flaws

(see 4.4.5.).

3.7 Sharp edges. Unless otherwise specified on the applicable specification sheet, sharp edges shall be

rounded, chamfered or broken, 0.15 to o.40 mm.

3.8 Identification marking. Nuts shall be marked in accordance with MIL-STD-130.

3.9 Workmanship. The workmanship shall be uniform in quality and appearance and free from hanging burrs

and slivers, gouges, porosity, objectionable scale or any other defects which may adversely affect the nut's

serviceability.

4. VERIFICATION

4.1 Classification of inspections. The inspections specified herein are classified as follows:

a.

Material inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2 Material inspection. Material inspection shall consist of certification supported by data verifying that the

materials used in fabricating nuts are in accordance with the requirements of 3.2 prior to such fabrication.

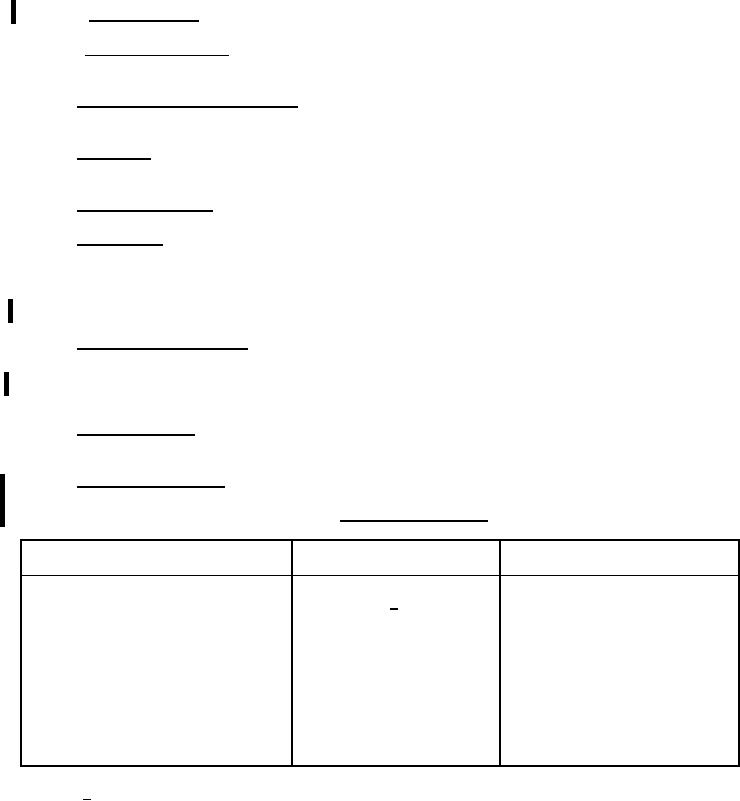

4.3 Conformance inspection. Conformance inspection shall be in accordance with table I.

TABLE I. Conformance inspection.

Inspection

Requirement

Test method

Paragraph

Paragraph

Group A

1/

4.4.1

Examination

Group B

4.4.2

Hardness

3.3.2

4.4.3

Surface roughness

3.4

4.4.4

Protective finish

3.5

4.4.5

Cracks, seams, inclusions, and flaws

3.6

Group C

Tensile strength

4.4.6

3.3.4

1/ All requirements not covered by tests.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business