MIL-DTL-70329A

4.3.1 Inspection lot. An inspection lot shall consist of all nuts covered by a single specification sheet, produced

under essentially the same conditions, and offered for inspection at one time.

4.3.2 Rejected lots. If an inspection lot is rejected, the contractor may rework it to correct the defects, or screen

out the defective units, and resubmit it for reinspection. Resubmitted lots shall be inspected using tightened

inspection. Such lots shall be separate from new lots, and shall be clearly identified as reinspected lots.

4.3.3 Sampling for group A inspection. Sampling shall be in accordance with ASQ Z1.4 inspection level II

with acceptance on zero and rejection on one for major defects. For minor defects, inspection level I with

acceptance on zero and rejection on one.

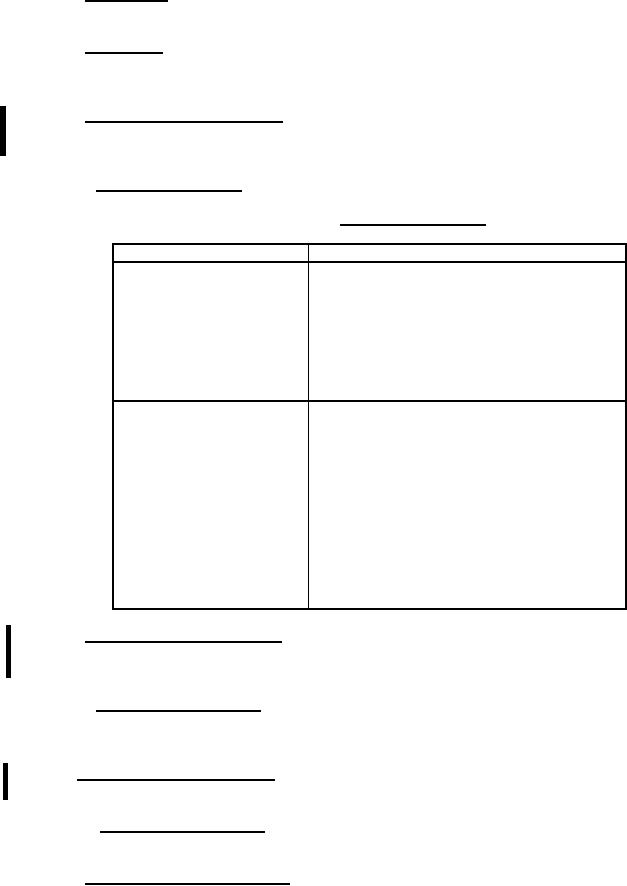

4.3.3.1 Classification of defects. Defects shall be classified as specified in table II.

TABLE II. Classification of defects.

Category

Defect

Critical

None defined

Major

101

Runout and parallelism of faces not as

Specified.

102

Threads not as specified.

103

Face diameter not as specified.

Minor

201

Thickness not as specified.

202

Outside diameter not as specified.

203

Protective finish, if applicable, missing.

204

Burrs or sharp edges.

205

Other dimensional characteristics not

covered above.

206

Workmanship not as specified.

207

Marking missing, incorrect, insufficient,

illegible or not permanent.

208

Packaging not as specified.

4.3.4 Sampling for group B inspection. Sampling shall be in accordance with ASQ Z1.4 inspection level S-2

with acceptance on zero and rejection on one and may be made on sample units which have been subjected to and

have passed group A inspection.

4.3.4.1 Disposition of sample units. Sample units which have passed all the group B inspection may be

delivered on the contract or purchase order if the lot is accepted and the sample units are still within specified

requirements.

4.3.5 Sampling for group C inspection. Sampling shall be in accordance with ASQ Z1.4 inspection level S-2

with acceptance on zero and rejection on one.

4.3.5.1 Disposition of sample units. Sample units which have been subjected to group C inspection shall not

be delivered on the contract.

4.3.6 Sampling for protective finish test. Sampling for protective finish test shall be in accordance with the

applicable specifications referenced in 3.5.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business